Oracle, Temporary Exhibition Site

Modular Building

Reading, Berkshire

PROJECT BACKGROUND:

Thames Valley Park is a high-tech business park and home of Oracle.

The corporation was opening a temporary exhibition site which included a kiosk, a hospitality suite, site cabins, an accessible toilet, a control cabin and an innovation lab with a demo railway station to showcase the capabilities of their technical software.

REQUIREMENT:

Temporary sustainable ramps are needed until the end of the site hire contract.

The client chose Rapid Ramp over a timber solution due to the product’s sustainability and recycling benefits.

Timber ramps are one-use systems which get thrown away after usage. As a result, there would have been additional costs on top of fabrication, including hiring a skip and appointing a labourer for removal.

We offered a rental package that included removal. Plus, unlike timber, our systems are 100% recyclable and reusable, reducing waste and maximizing the life value of the products.

At the end of the hire period, the systems will be dismantled and collected as part of our recycling rotations. The components get stored in our warehouse, so they can be dispatched to another site and used again.

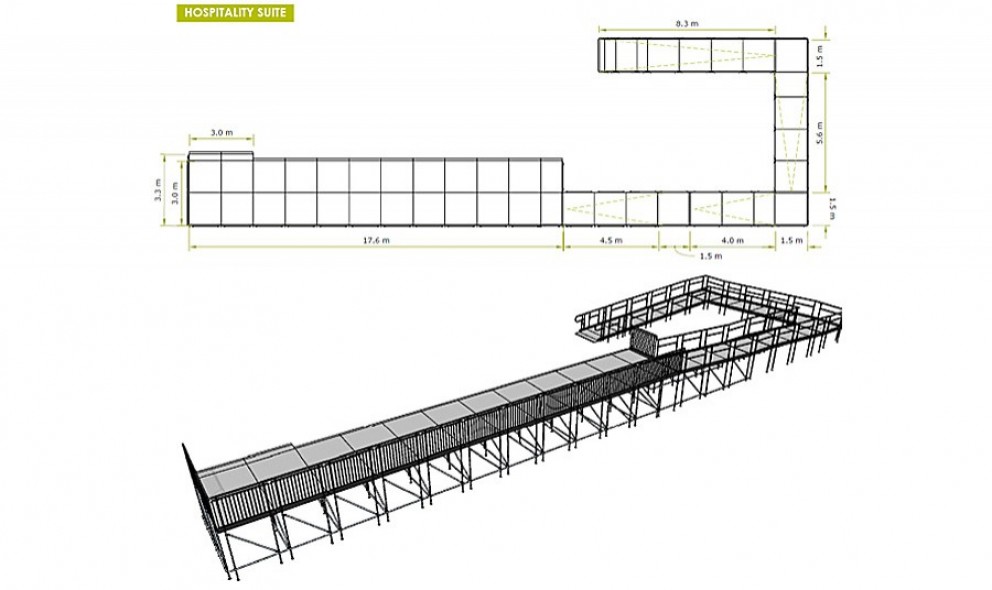

CAD DRAWINGS:

END RESULT:

The installation was completed over two weeks.

Ramped access was provided to the kiosk, hospitality suite, control cabin, accessible toilet, and site cabins.

The platforms include a 1:15 gradient.

The control cabin was at an elevated threshold height; therefore, this ramp had extra support under the platform legs by cross-bracing longer-length tubes.

Once the exhibition closes, the systems will be dismantled, removed, and placed in our recycled stock rotations.

FEATURES INCLUDED:

- Trombone Ends - these are added to the ends of a Rapid Ramp to prevent clothes catching.

- Mesh Platform - the self-draining mesh allows water to pass through rather than collect on the surface.

- Standard Continuous Handrail - this handrail system ensures users always have support to hold onto.

- Black Powder Coated Finish – rails are coated with thermosetting powder to provide a non-conductive, non-slip, scratch-resistant surface that is tougher than conventional paint.

EXTRA FEATURES INCLUDED:

- Infill Handrail - this product prevents users from climbing or falling through gaps.

- Yellow Tread - this is a safety feature designed to help those with impaired vision identify the nose of the ramp and any level changes.

- Rest Platform – a rest platform at 5 metres is required to allow the user to pause.

- 1100mm High Rail – these handrails attach to any level sections.

SUSTAINABILITY & RECYCLING AT RAPID RAMP:

We dedicate ourselves to reducing the impact our products, services, and activities have on the environment. It is increasingly clear that we need to transition to a low-carbon economy, and with our reusable components, and sustainable benefits, we are rapidly working towards this.

Measures presently implemented include:

✓ At every stage of the manufacturing process, we use the full capacity of the transport available. This reduces the number of trips between the manufacturing facilities and the warehouse. Plus, it decreases the emissions created per product.

✓ All used cardboard is recycled.

✓ All office and warehouse staff are local. Home working is possible, and staff are encouraged to use public transport.

✓ When possible, region-specific Rapid Ramp fitters are utilised to reduce emissions from long car journeys.

✓ The modular Rapid Ramp & steps are 100% recyclable and reusable, reducing waste and maximizing the life value of the products.

✓ All Rapid Ramp components are stocked in our warehouse and manufactured in the UK, rather than overseas.

✓ Damaged components unsuitable for our reconditioned rotations are recycled. The material can be melted down and recast into other items.

HAVE A SIMILAR REQUIREMENT?

REQUEST A QUICK PRICE

Estimates can be returned within 24hrs if there is clear information given, including project address, drawings, photos and contact details.